I. Industry Overview

The grain, feed, and food industries generate significant amounts of dust during processing, conveying, mixing, and packaging operations. While seemingly ordinary, this dust exhibits highly flammable, explosive, hygroscopic, and bag-clogging properties, constituting a classic high-risk dust environment.

Common dust types include:

Grain dust: e.g., wheat flour, corn flour, rice husk powder;

Feed dust: e.g., fish meal, soybean meal, premix powder;

Food dust: e.g., flour, powdered sugar, milk powder, seasoning powder.

These dust particles typically range from 1–100μm in size, being fine, lightweight, and highly dispersible. When mixed with air to form a certain concentration (30–200g/m³), they can explode upon encountering open flames, electrical sparks, or static electricity. Therefore, dust collection systems in the grain and feed processing industries must not only achieve high dust removal efficiency but also prioritize explosion prevention, fire protection, and reliable safety.

II. Dust Generation Stages

Dust in grain processing and feed production primarily originates from the following stages:

Raw Material Receiving and Conveying: Severe dust generation occurs during grain unloading, elevator operations, and screw conveyor transfers due to material impact.

Grinding and Mixing: The outlets of grinders and mixers exhibit the highest dust concentrations, with particles readily becoming airborne.

Packaging and Weighing: Noticeable dust generation occurs during material filling, bag sealing, and weighing processes;

Drying and Cooling: Temperature fluctuations cause dust to coexist with moisture, significantly increasing the risk of bag clogging;

Storage Silos and Ventilation Ports: Accumulated dust poses long-term explosion hazards.

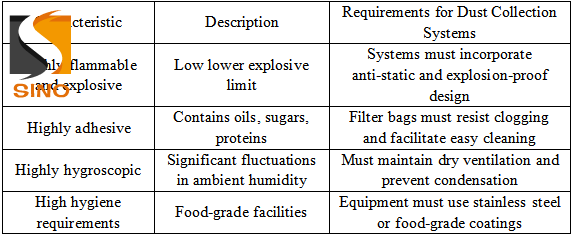

III. The Unique Characteristics of Dust in the Grain Industry

IV. Technical Advantages of Pulse Dust Collectors

High-Efficiency Dust Removal:

Utilizes high-pressure pulse reverse-blow cleaning with dust removal efficiency ≥99.9%, effectively capturing fine particulate matter to achieve emissions below 20mg/Nm³.

Explosion-Proof Safety Design:

Equipped with explosion relief ports or explosion vents to rapidly release pressure during anomalies;

Interior walls, filter bags, and ductwork utilize anti-static materials to prevent electrostatic buildup igniting dust;

Electrical systems incorporate explosion-proof motors and explosion-proof control cabinets for operational safety.

Anti-Bag Clogging & Anti-Condensation Design:

Utilizes membrane-coated filter media or PTFE filter bags with smooth surfaces to minimize dust adhesion;

Incorporates insulation layers and heating devices to prevent condensation caused by excessive temperature differentials;

The cleaning system employs a dual-control mode of timed + differential pressure to ensure long-term unobstructed filter bags.

Food-Grade and Sanitary Structure:

The equipment's inner walls are made of 304 or 316 stainless steel;

Filter bags use food-grade polypropylene or PTFE filter materials;

Internal welds undergo polishing treatment, eliminating dead corners and dust residue, meeting food hygiene standards.

V. Structural Design and Selection Criteria

(1) Airflow Organization:

Grain dust is lightweight and easily suspended. An upward air intake and downward exhaust configuration is recommended to allow airflow to settle downward, preventing dust recirculation.

(2) Filtration Velocity Control:

Grain dust is fine and prone to clogging. Control filtration velocity ≤ 1.0 m/min (1.2–1.5 m/min for general dust).

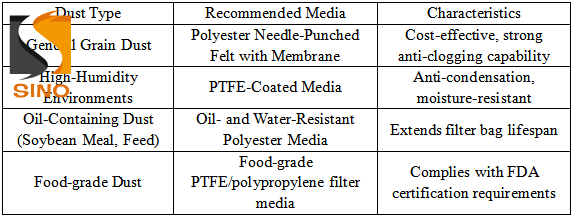

(3) Filter Media Selection:

(4) Explosion-proof design essentials:

Install explosion vents or rupture discs; vent direction must avoid personnel passageways;

Electrical components require explosion-proof control boxes and static grounding;

Pipelines, hoppers, and fan systems must be fully grounded;

Direct connection to high-temperature equipment is prohibited.

VI. Typical Application Cases

Case 1: Dust Removal in Flour Mill Packaging Workshop

Flour dust is fine, highly adhesive, and potentially explosive. The facility employs a food-grade stainless steel pulse-jet dust collector with PTFE-coated anti-static filter bags.

Filter velocity: 0.9 m/min

Cleaning Method: Constant-pressure-differential pulse jet cleaning

Emission Concentration: ≤15mg/Nm³

The system has operated stably for 3 years without bag clogging or explosion incidents.

Case 2: Dust Collection for Feed Mill Grinding System

Feed dust exhibits high oil content and fine particle size, causing frequent bag clogging in the original dust collector. After replacing with an oil- and water-resistant pulse jet baghouse:

Filter bag lifespan doubled;

System resistance reduced by 30%;

Workshop dust concentration decreased from 120mg/m³ to 6mg/m³.

VII. Operation, Maintenance, and Safety Management

Daily Inspection: Monitor differential pressure, fan current, and ensure proper operation of the pulse-jet cleaning system;

Regular Ash Removal: Prevent ash bridging in hoppers;

Adjustment of Cleaning Cycle: Automatically optimized based on differential pressure changes;

Fire and Explosion Prevention Inspection:

Weekly testing of grounding resistance;

Periodic inspection of explosion venting discs and spark detection devices;

Filter Bag Maintenance: Replace damaged bags promptly; strictly prohibit operation with dust accumulation;

Environmental Hygiene: Maintain dust-free storage areas around the dust collector.

VIII. Environmental Protection and Economic Benefits

Installing pulse dust collection systems in the grain and feed industry significantly enhances production environments and safety standards:

Dust emissions reduced by over 95%;

Workshop air cleanliness meets the “Industrial Enterprise Dust Hygiene Standards”;

Minimized powder loss, recovering approximately 3–5 tons of usable materials annually;

Prevents fire and explosion risks, ensuring employee safety;

Elevates corporate brand image and food safety ratings.

IX. Conclusion

Dust control in grain, feed, and food industries concerns not only environmental protection but also safety and lives. Pulse jet baghouse dust collectors, with their advantages in high-efficiency filtration, explosion and static prevention, anti-bag clogging, and anti-condensation, have become standard equipment in the industry.

Future trends will integrate dust collection systems with intelligent monitoring, explosion-proof alarms, and energy consumption management systems to achieve fully automated, digital, and traceable dust collection safety systems.

Contact: Jane

Phone: +86-136 0202 1569

E-mail: info@sinobaghouse.com

Add: No.14 Building, Jingjin Shishang Plaza, Wuqing District, Tianjin, China