A. Introduction to baghouse dust collectors

The bag filter is a dry dust collection device. It is suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of textile filter cloth or non-woven felt, using the filtering effect of the fibrous fabric to filter the dusty gas. When the dusty gas enters the bag filter, the particles and the dust with a larger specific gravity will settle down due to gravity and fall into the dust hopper, while the gas containing the finer dust is retained and filtered when passing through the filter media, so that the gas is purified.

After using the filter media for a period of time, due to sieving, collision, retention, diffusion, electrostatic and other factors, a layer of dust accumulates on the surface of the filter bag, this layer of dust for the initial layer, in the future movement process, the initial layer instead of becoming the main filter layer of the filter media, by the role of the initial layer, the filter media with larger mesh can also get a higher filtration efficiency. With the accumulation of dust on the surface of the filter media, the efficiency and resistance of the dust collector are increasing accordingly, when the pressure difference between the two sides of the filter media is relatively large, it will squeeze over some fine dust particles that have been attached to the filter media, thus making the dust collector efficiency drop. In addition, the high resistance of the dust collector will also cause the air volume of the dust removal system to drop significantly. Therefore, after the resistance of the dust collector has reached a certain value, it needs to be cleared in time. And when clearing the dust, the initial layer must not be destroyed, so that the efficiency does not drop.

B. The advantages of bag-type dust collector

1, dust removal efficiency is relatively high, can trap particle size greater than 0.3 microns of fine dust, dust removal efficiency can reach more than 99%. The dust concentration at the outlet of the dust collector can be controlled within tens of mg/m3, and there is a high classification efficiency for fine dust of submicron particle size.

2, flexible usability, wide range of air volume, from hundreds of cubic metres per hour to hundreds of thousands of cubic metres per hour, can be set up directly in the room, placed near the machine tool to make a small unit, or can be made into a large dust chamber and placed outdoors. It can also be used for de-dusting the flue gas of industrial furnaces to reduce the emission of air pollutants.

3, simple structure, stable operation, low initial investment (compared with electric dust collector), relatively easy maintenance. Therefore, the bag type dust collector is widely used in eliminating dust pollution, improving the environment and recycling materials.

4, dust disposal is relatively easy, the bag filter is a dry purification equipment, no water is needed, so there is no sewage treatment or mud treatment, and the collected dust can be easily recycled.

5, to ensure the same high dust removal efficiency premise, the cost is lower than the electric dust collector. When glass fibre, PTFE, P84 and other high temperature resistant filter media can be used, they can be operated under high temperature conditions above 200°C.

6, insensitive to the characteristics of the dust, not affected by the dust and resistance, all kinds of dust and resistance can be matched to the appropriate filter bag material.

C. Classification of bag filter

According to the national standard "Classification of bag dust collectors and performance indication of specifications", bag dust collectors can be divided into five categories. The cleaning method is the main criterion for the classification of bag filter:

1, mechanical vibration

Bag dust collectors with mechanical devices (including manual, electromagnetic or pneumatic devices) to make the filter bags vibrate so as to achieve the purpose of dust cleaning, and are divided into non-compartmental structure suitable for gap work and continuous work of two forms of structure of the bag dust collector.

2, split chamber blowback type

The bag dust collector is divided into two types of structure: non-compartmental and continuous.

3, nozzle blowing back class

Through the high-pressure fan or compressor to provide counter-blowing airflow, through the mobile nozzle to blow back, so that the bag deformation shake and penetrate the filter material to clear the dust bag dust collector (are non-compartmental structure).

4, vibrating and blowing back with class

Mechanical vibration (including electromagnetic vibration or pneumatic vibration) and counter-blowing are used to clear the dust in two ways (all in a separate chamber).

5, pulse blowing

Compressed air is used as the power to clean the dust, using the compressed air released by the pulse blowing mechanism instantaneously, inducing several times the secondary air to shoot into the filter bag at high speed, causing the bag to bulge sharply, relying on impact vibration and reverse airflow to achieve the purpose of cleaning the dust bag dust collector.

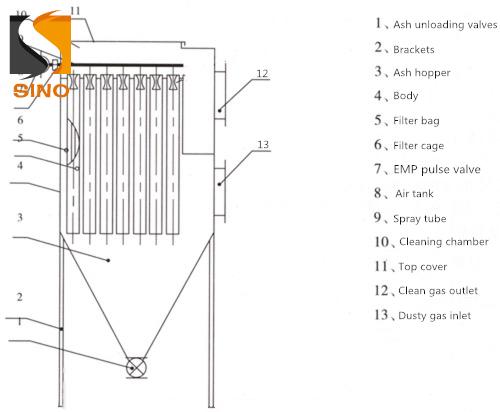

D. Bag filter structure diagram.

Bag filter body structure is mainly composed of upper box, middle box, lower box (ash hopper), ash cleaning system and ash discharge mechanism.

In addition to the correct choice of filter bag material, the dust cleaning system plays a decisive role in the performance of the bag filter. Therefore, the dust cleaning method is one of the methods to distinguish the performance of the baghouse and is a more important part of the baghouse operation.

The structure is shown in the following diagram:

E. Daily operation of baghouse dust collectors

The operation of the bag filter can be divided into trial operation and daily operation.

First of all, for trial operation, every single part of the system must be checked, then adaptable operation is done and partial performance tests are to be done.

In daily operation, the necessary checks should also be carried out, especially on the performance of the baghouse. It is important to note that changes in the load on the host machine can have a large impact on the performance of the dust collector. After the machine has been started, close attention should be paid to the working conditions of the baghouse dust collector and the relevant records should be kept.

Contact: Jane

Phone: +86-136 0202 1569

E-mail: info@sinobaghouse.com

Add: No.14 Building, Jingjin Shishang Plaza, Wuqing District, Tianjin, China