"SINO" series vertical mixer is divided into ordinary type and heating drying type, which is suitable for mixing, drying, color mixing, and storage of various plastics. In particular, a variety of new and old materials, plastic, and masterbatch mix are better.

Introduction of Mixing Agitator

"SINO" series vertical mixer is divided into ordinary type and heating drying type, which is suitable for mixing, drying, color mixing, and storage of various plastics. In particular, a variety of new and old materials, plastic, and masterbatch mix are better.

Vertical mixer plastic particle mixer can be used for mixing raw materials (nozzle, color masterbatch, chemical powder, etc.) before pelletizing, and can also mix the same batch of orders of manufactured particles. Different raw materials caused by different periods of time can be mixed in a centralized and one-time way so that the whole batch of materials can be consistent from nature to color, so as to improve production efficiency and product quality.

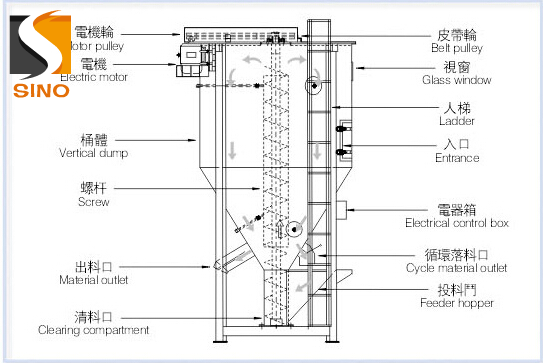

Structure of Mixing Agitator

Mixing Agitator main parts include mainframe, mixing barrel, feeding port, discharging port, motor, mixing screw, etc. The motor directly drives the mixing screw, so that the plastic can rotate and mix in the mixing barrel circularly, and the effect is more uniform.

Working principle

1. Common type: the mixing principle of the vertical mixer is to screw the materials to the upper end of the can body, and then drop them in the shape of an umbrella and continuously mix them up and down circularly, so as to achieve the purpose of even mixing.

2. Heating type: the hot air of the traditional dryer enters from the lower side of the can body. Because the raw materials are still, the hot air is difficult to penetrate, which causes the phenomenon of the temperature of the upper part of the lower part of the dryer. Sometimes, the raw materials are sintered due to the local overheating, causing the blockage, making the hot air more difficult to enter other areas, so the expected drying effect cannot be achieved. The machine is designed to transport two-stage spiral pulp. The first stage will send the raw materials into the barrel. The second stage will lift the raw materials to the upper part of the barrel and scatter them in an umbrella shape. The hot air will blow out from the center of the lower part of the barrel to all sides and smoothly penetrate from the gap between the moving raw materials so that the raw materials can be fully heated under dynamic conditions.

Features of Mixing Agitator

· Easy operation and maintenance (Vertical Design)

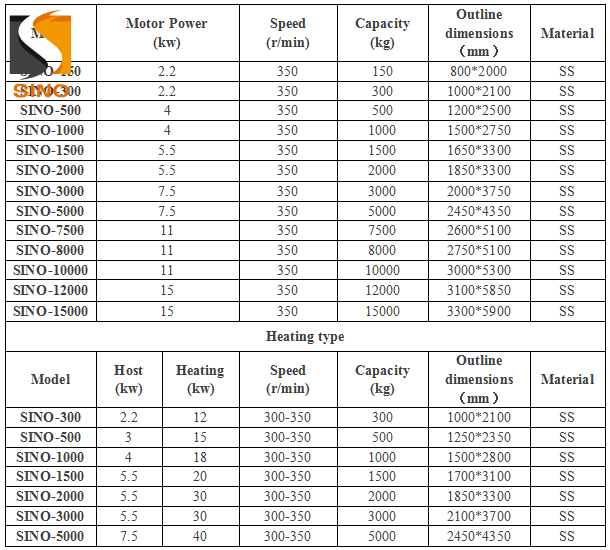

· Standing 1-15t model for customers first (Optional Capacity)

· Stainless steel, easy to clean and rust-free (Easy Clean)

· Fast mixing speed, ensuring the consistency of each batch of materials (Even Mixing)

· It has the advantages of small investment, quick effect, less land occupation, labor-saving, high efficiency (Cost Saving)

· Can be customized according to the high requirements of the customer workshop (Can be Customized)

Application Fields

It is widely used in: plastic sheet material, grinding material, plastic particles, new and old plastic materials and adding color masterbatch to mix evenly.

* Plastic material plant

* Pelletizing plant

* Plastic bag plant

* rubber plant

* Plastic products plant, etc.

Products Specifications

Contact: Jane

Phone: +86-136 0202 1569

E-mail: info@sinobaghouse.com

Add: No.14 Building, Jingjin Shishang Plaza, Wuqing District, Tianjin, China