Centrifugal fan is according to the principle of kinetic energy converted to potential energy.

Introduction

Depend on the input mechanical energy, The Centrifugal fan is the machinery what will improve the pressure side by side to send gas. It is a kind of driven fluid machinery. Centrifugal fan air blower is widely used in factories, mines, tunnels, cooling towers, vehicles, ships, and the structure of the ventilation, dust and cooling; The ventilation of the boilers and industrial furnaces and induced wind; Air conditioning equipment; Household appliances in cooling and ventilation; Grain drying and submitted; Wind tunnel and become a hovercraft inflatable and propulsion, etc.

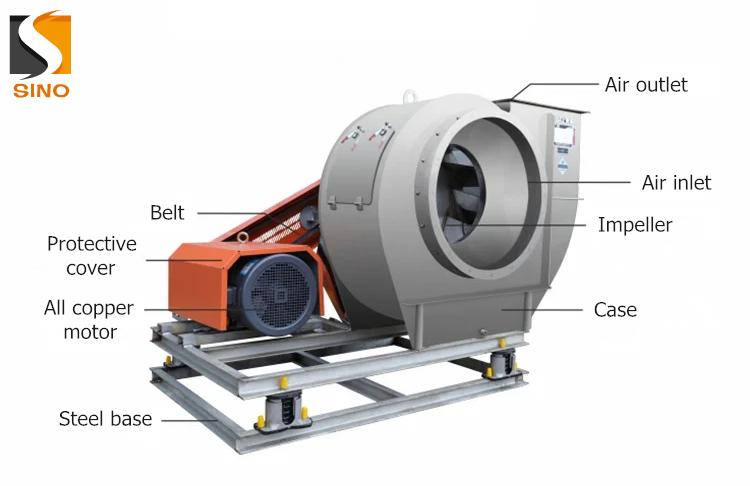

Structure composition

Centrifugal fan consists of chassis, main shaft, impeller, bearing transmission mechanism and motor, etc.

Fan shell: Made of steel plate. It can be divided into full open and half open. The half open is easy to facilitate maintenance.

The shell is made by ordinary steel welded volute casing. The cabinet can be made in two different type: One is cases made whole, it can’t be opened. The other cases is made three open types. In addition to divide the plane into two and a half outside, the upper side along vertical center line again divided into two, use the bolt for connection.

Air inlet: it can be made as convergence type streamlined structure, To adopt bolt fix it at the fan entrance.

Impeller: composed of the blade, curve of front coil and after plate. In solitary cone of welding wheel cover and flat roulette, it is 12 pieces pour wing shape blade. All material adopt steel manufacturing. Through the static dynamic balance, the impeller can get the good performance, high efficiency, and stable operation.

Rotor:It should be made of the dynamic balance and static balance. To ensure the steady running, good performance.

Transmission parts: It is composed of main shaft, bearing box, rolling bearing and belt pulley (or coupling). The main spindle, bearing box, rolling bearing, driving belt or coupling etc. Spindle made by the high quality steel. One type is: bearing box whole structure, a thermometer in the oil and mark for bearing. The other type is: fan tied for bearing bouse, with a thermometer in bearing house, to adopt bearing grease lubrication for bearing.

Working principle

Centrifugal fan is according to the principle of kinetic energy converted to potential energy. To use of high-speed rotation of the impeller speed, The gas will speed up and then slow down. To change the gas flow direction, the kinetic energy is converted into potential energy (pressure). In single stage centrifugal fan, the gas from the axial impeller, changed into radial gas flows through the impeller, and then into the diffuser. In the diffuser, gas changed direction of flow and caused slowdown, the deceleration function converts kinetic energy into pressure. The impeller will increase pressure in first. And then, the diffusion process will increase the pressure again. In multistage centrifugal fan, air burning into the next impeller, with reflux device make higher pressure.

Features

• IP 55/65

• 50hz/60hz

• Corrosion Proof

• 220v/380v/415v/440v/660v/1140v

• 1450RPM/960RPM/720RPM/590RPM

• High Temperature Proof (up to 400 °C)

• Each fan's impeller has been well dynamic balanced.

1.CHARACTERISTIC CURVE of each equipment available.

2.Photographs of the equipment available.

3.Parts manual available.

Application fields

It’s applicable to industries those are easy to produce high density dust and dust with large particle sizes.

* Soldering, wave soldering, reflow soldering

* Laser welding, engraving, marking, cutting

Specification detail

Working Temperature: < 400 degree

Air composition: Clean air, Dusty air, Corrosive gas, Combustible gas

Dust composition: Powder materials, Light particle materials, etc.

Performance:

Impeller diameter: 800~1600 mm

Speed of mainshaft: 960~2900 rpm

Pressure range: 2705~15425 Pa

Flow range: 3297~63305 m3/h

♦ Impeller Type: Backward/Forward/ radial blade

♦ Driving Mode: Direct/belt/Coupling drivetrain

♦ System Type: Single inlet type, Overhang type.

♦ Cooling Type: Air cooling/Circulating Water cooling

♦ Bearing Lubrication Methods: Grease lubricating/Oil bath lubrication

Configuration

Motor Brand: SIEMENS, ABB, SEW,TECO, motor can be choosed by customer.

Impeller: Carbon steel

Impeller cone (Air Inlet): Carbon steel

Case: Carbon steel

Air damper: Carbon steel

Main shaft: High-strength carbon structural steel

Bearing: FAG, SKF, ZWZ, C&U, Bearing can be choosed by customer

Bearing housing: Cast iron

Drivetrain: Coupling

Foundation bolt: Steel

♦ Basic Components:

Motor, Impeller, Impeller cone (Air Inlet), Case, Main shaft,

Bearing, Bearing housing, Pin coupling, Foundation bolt.

System monitoring Instrument, Lube system, Overhead lube tank...

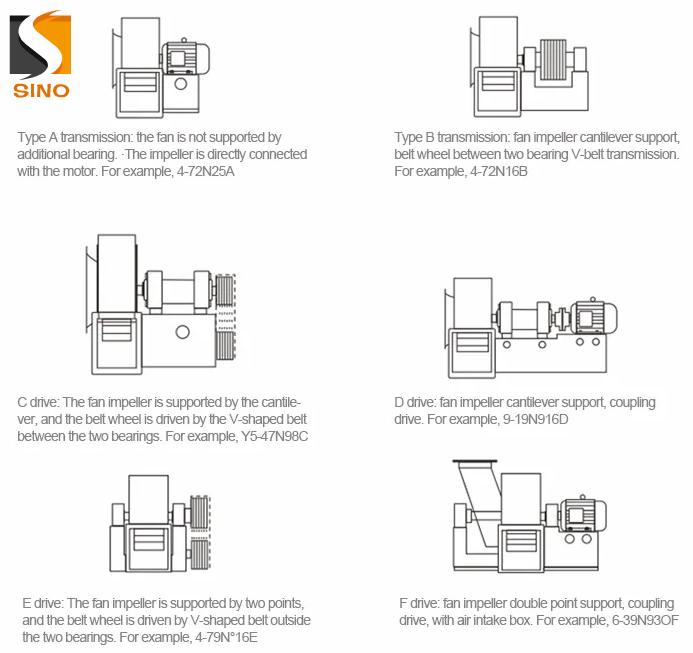

Fan Drive Mode

Contact: Jane

Phone: +86-136 0202 1569

E-mail: info@sinobaghouse.com

Add: No.14 Building, Jingjin Shishang Plaza, Wuqing District, Tianjin, China